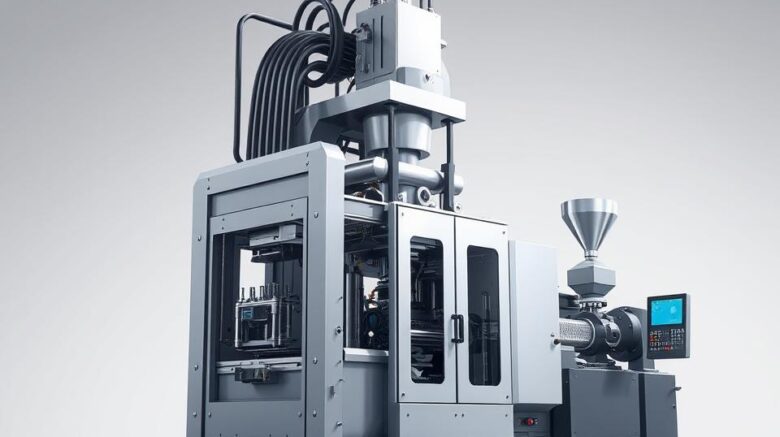

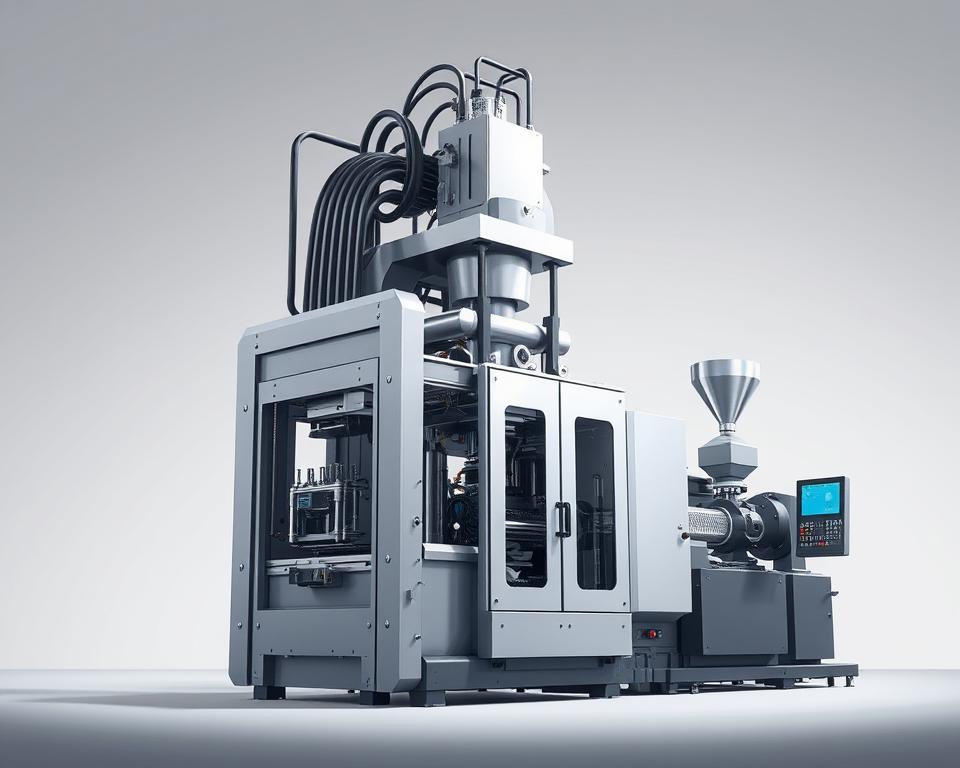

How to Identify Top Injection Molding Services in China

The important meeting has recently finished, your new project has the green light, the timeline is aggressive, and the budget is… well, let’s just say it’s tight.. Then someone—maybe your boss, maybe the finance director—utters the phrase that sends a little jolt down every project manager’s spine: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. The potential savings can be massive. Yet your thoughts are already spinning. You’ve heard the stories, haven’t you? The nightmare of defective parts, opaque communication, and delayed, off-spec shipments. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

However, here’s the reality. Sourcing plastic mold doesn’t have to be a gamble. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Ignore the nightmare anecdotes. Let’s walk through a real-world playbook for getting it right.

First Things First: Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This becomes the bedrock of your sourcing project.

What should you include?

Begin with 3D CAD models. These are non-negotiable. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

But 3D isn’t enough. Include precise 2D engineering drawings. This details critical info missing from the 3D file. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Don’t just say “Plastic.” Don’t even just say “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. Why so detailed? Because there are thousands of plastic variations. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

They can offer alternatives, but you must provide the initial spec.

Finally, include the business details. What’s your forecasted annual volume (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

Okay, your RFQ package is a work of art. who gets your RFQ? Online sourcing is global but crowded. Finding suppliers is simple; finding quality ones is tough.

Begin on popular marketplaces such as Alibaba or Made-in-China. They offer breadth but not depth. Treat them as initial research tools, not final solutions. Aim for a preliminary list of 10–15 potential partners.

However, don’t end your search there. Consider using a sourcing agent. They do cost extra. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. On your first run, this is like insurance. It’s schedule protection.

Another tactic: trade exhibitions. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Plus, ask peers for referrals. Ask other project managers in your network. A solid referral can be more valuable than any ad.

Sorting the Contenders from the Pretenders

After firing off that RFQ to a broad pool, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It’s a bit of an art and a science.

Begin with responsiveness. Do they respond quickly and clearly? Can they handle detailed English exchanges? But here’s the real test: Are they asking you intelligent questions? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” Consider that a big green light. It shows they’re engaged and experienced. A “Sure, no issues” vendor often means trouble.

Then confirm their machinery specs. Request their machine list. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. This is not optional. Just as you interview hires, audit suppliers. Either visit in person or engage a local audit service. They perform a one-day factory inspection. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. It’s a tiny cost for huge peace of mind.

Transforming CAD into Real Parts

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Now the process kicks off.

Your supplier’s first deliverable is a DFM analysis. DFM stands for Design for Manufacturability. It’s their professional review of your CAD. It will highlight potential issues like areas with thick walls that could sink, sharp corners that could cause stress, or surfaces without enough draft angle for clean ejection from the mold. Comprehensive DFM equals a top-tier supplier. It becomes a joint effort. You iterate with their team to optimize the mold.

With DFM sign-off, toolmaking begins. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are your initial mold shots. They are your moment of truth.

Expect T1s to need tweaks. This is normal! Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold company parts arrive. It could require several iterations. Plan for this loop in your schedule.

At last, you get the perfect shot. Dimensions, finish, and performance all check out. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Now comes full-scale production. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. Typically, this means a pre-shipment audit. Use a third-party inspector again. They’ll randomly select parts, compare them to specs and golden sample, and deliver a detailed report. They provide a photo-filled inspection report. Only after you approve this report do you authorize the shipment and send the final payment. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It’s about building a relationship with your supplier. Treat them like a partner, not just a line item on a spreadsheet. Transparent dialogue, respect, and process discipline win. Certainly, it’s complex. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re ready.