Expert Mold Design Services in Houston

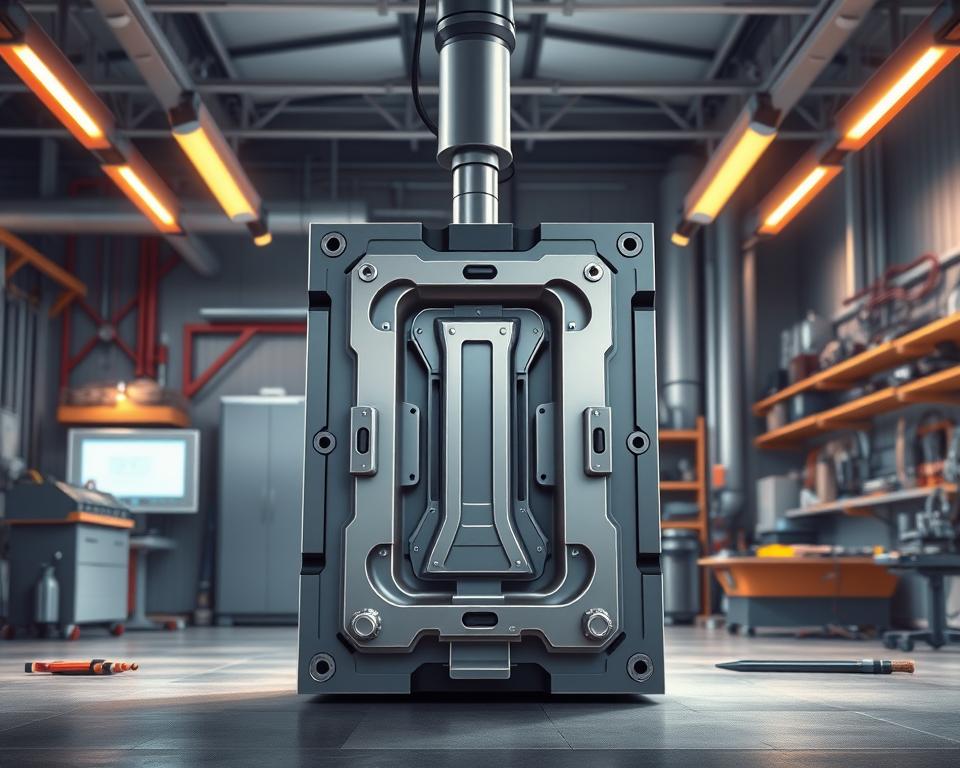

By 2025, the global injection molded plastics market will reach $440 billion. Such expansion highlights why expert mold design is essential. They develop precision mold designs tailored to varied industries. Houston’s Lowrance Machine stands out as a premier mold design firm. They provide cutting-edge mold solutions for the automotive, aerospace, and consumer-goods markets.

Lowrance Machine uses advanced technologies like CAD software and 3D printing. Their experts guarantee both accuracy and speed throughout molding. Backed by deep expertise and technical know-how, they remain a trusted business ally. Explore how their injection molds Houston services can improve your projects and meet today’s market demands.

Why Mold Design Services Matter

Quality and efficiency in manufacturing hinge on expert mold design services. The role of mold design is immense; it shapes the performance and longevity of products. By prioritizing professional mold design, firms reduce costs and improve quality measures.

Lowrance Machine showcases the value of working with seasoned professionals. They engage closely with clients to develop tailored designs. By employing cutting-edge methods like 3D modeling and CAD, they help businesses create molds that adhere to high standards.

Choosing top-notch mold design services boosts product performance and drives business success. Streamlined mold design fosters efficient production and sharpens competitive stance.

Mold Design Houston: Types of Services Offered

At Lowrance Machine in Houston, you’ll find varied mold design solutions designed for every industry. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Design Services: Custom mold design solutions that cater to unique specifications and requirements.

- Prototyping: Creation of prototype injection molds to test product designs before mass production.

- Injection Mold Fabrication: Precision-engineered injection molds built to last.

- Advanced 3D Design: Utilization of advanced software to create detailed 3D models of molds, improving design accuracy.

- Maintenance Services: Preventive and corrective mold maintenance to prolong tool life.

All offerings focus on efficient production, improved product standards, and cost savings. Knowing the service spectrum lets companies tailor mold design to their operational objectives.

Why Hire Professional Mold Designers

Partnering with seasoned mold designers yields multiple manufacturing benefits. These benefits include enhanced accuracy, durability, and efficiency. Bespoke design drives superior product standards and uniformity.

Experienced mold design experts offer insights that streamline production. They certify molds comply with both generic and custom criteria. This collaboration fosters innovation and improves product lifecycles.

Economical operations are a key perk. Modern techniques curb scrap and shorten lead times. These improvements lead to better budgets and healthier profit margins. Swift design workflows speed time-to-market, sharpening competitive positioning.

Overall, professional mold services underpin manufacturing success. They focus on boosting throughput and product excellence.

Next-Gen Mold Design Innovations

The field of mold design has seen a major leap forward thanks to technological advancements. Lowrance Machine leads the way with its cutting-edge mold design techniques. These innovations boost productivity and improve product quality. Advanced mold design technologies play a significant role, streamlining the creation of unique molds and cutting down on time and costs.

3D-print-driven prototyping excels at rapid, complex mold creation. It cuts scrap dramatically versus conventional tooling. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

Locally, mold designers in Houston leverage these advanced practices. Companies are gaining a competitive advantage by leveraging digital design tools and advanced fabrication methods. These technologies enable a more agile and responsive mold design process, meeting a wide range of client needs and market demands.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Harnesses 3D-printer tech for swift mold fabrication. | Shortens delivery times and cuts scrap. |

| Simulation Software | Enables digital prototype testing and refinement. | Enhances accuracy and optimizes performance. |

| CAD Platforms | Utilizes CAD/CAM for exact design work. | Supports bespoke specifications and rapid revisions. |

Final Thoughts

Mold design services are critical for businesses aiming at efficient manufacturing and high-quality production in Houston. These services bring specialized know-how to overcome mold design hurdles. They ensure that each company’s unique needs are met, leading to better outcomes.

As a leader in accuracy and client partnership, Lowrance Machine stands out. The benefits of mold design, such as customized solutions and cutting-edge technologies, help manufacturers stay ahead in a fast-changing market. Engaging experts boosts standards and refines processes.

Investing in professional mold design in Houston focuses on quality and efficiency. Businesses can meet customer expectations effectively and gain a significant competitive advantage. Embracing these expert offerings is key to thriving in a challenging marketplace.